Wisconsin ginseng farmers work hard everyday to take care of their ginseng gardens for 4 to 6 years before harvest (because 3-year-old ginseng needs 4 years of work, first year for land preparation) like taking care of their babies. Those ginseng roots that survive the insect’s bites, plant diseases, the Mother Nature especially the August summer heat, etc…will be harvested in fall. But one last step is crucial to obtain a good quality ginseng that cannot be taken lightly: DRYING. If this step turns wrong, the beautiful roots could become unwanted ginseng, which lower widely the value of the products. It sounds like easy science but a lot of farmers still unable to have it done right. Imagine a kiln (ginseng dryer) loaded with 10,000 pounds of fresh ginseng roots at once, the equivalent of 7,100 pounds of water has to be taken out of the roots within about 10 days at constant temperature of 100 F. Let's see some photos below.

Photo #1: Just came out from the ground, dirty roots.

Photo #2: After taking a shower before going into the dryer.

Photo #3: Roots affected by plant diseases have to be picked out before drying.

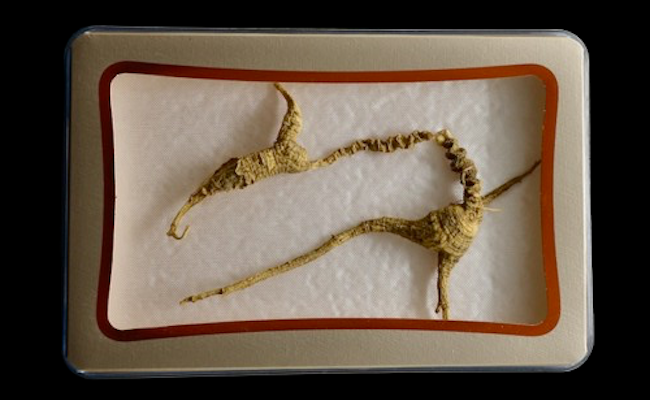

Photo #4: These are good dried roots.

Photo #5: But some bad dried (this is due to the dryer failed in the first few day of the drying process, this happens often when the outside temperature of the dryer was too high).

Photo #6: Another bad dried (this is due to uneven temperatures in different spot within the dryer. Temperature too high, roots interior turn brown; too low, it turns green. The perfect colour shall be vanilla white). *This photo comes from the web.

Don't think the farmers are dumbs...they feed you city guys... ;-)

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.